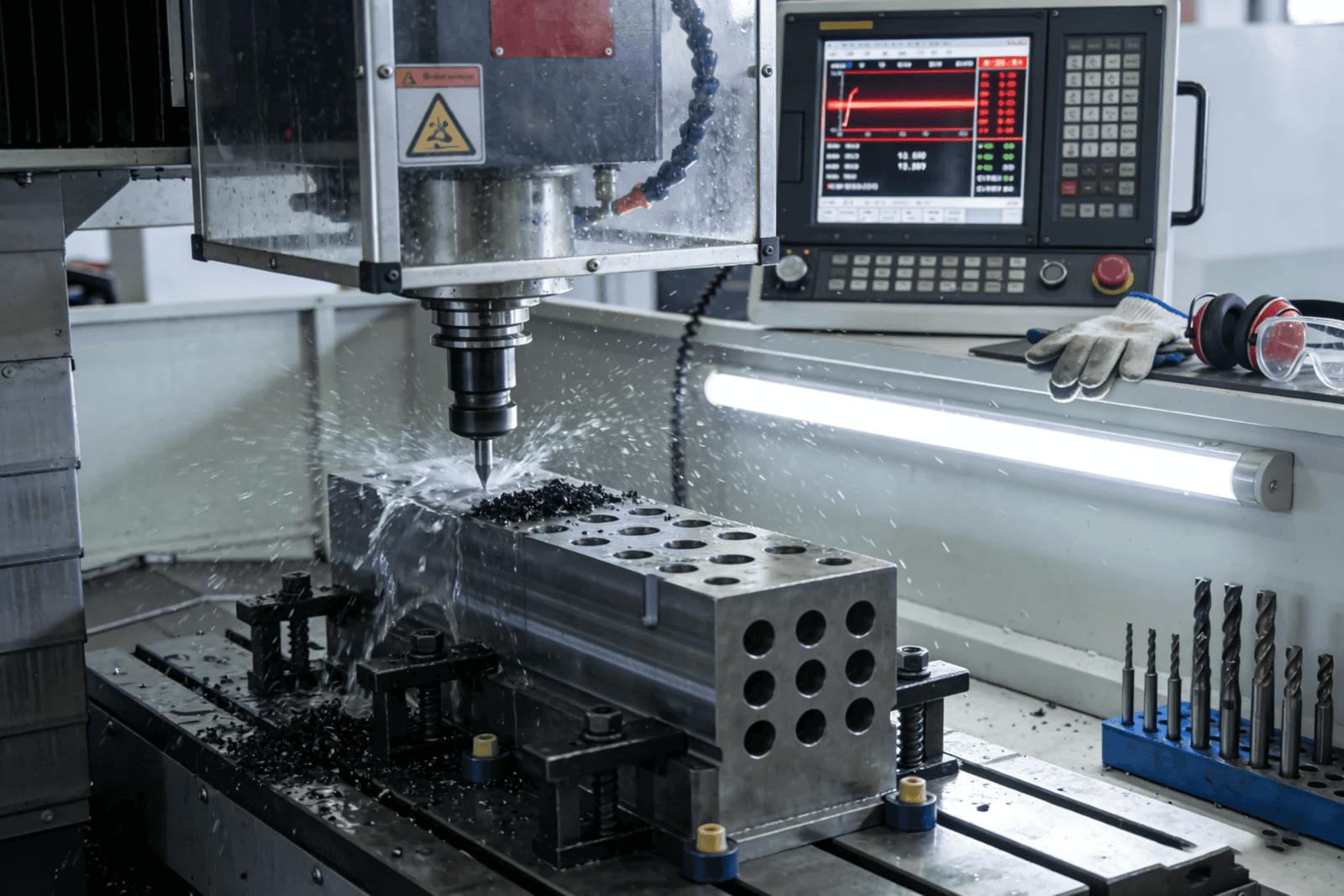

Are slow drilling speeds and constant bit changes hurting your shop's productivity? It's frustrating and costly. A high-value solid carbide drill set1 will completely change your workflow.

A high-value solid carbide drill bit set is defined by its material grade2, advanced coatings3, precise geometry4, and a useful range of sizes. These factors ensure superior speed, long life, and lower cost-per-hole5 compared to standard HSS bits, making it a smart investment for any machine shop.

I've seen many shops make the mistake of buying the cheapest set they can find, only to regret it later. The real value isn't in the initial price tag. It's about performance, longevity, and how the tool contributes to your bottom line. Let's break down what really matters when you're choosing your next drill bit set.

Why Choose a Solid Carbide Set Over HSS?

Are your high-speed steel (HSS)6 bits struggling with modern materials? The slow speeds and constant wear are frustrating. Solid carbide is the upgrade you need for superior performance.

Choose solid carbide over HSS for drastically higher cutting speeds7 and feed rates—often 3 to 5 times faster. Carbide's superior rigidity8 means better hole accuracy, while its wear resistance9 results in a longer tool life and a lower overall cost-per-hole, despite the higher initial price.

The difference really comes down to the material. Solid carbide is made from tungsten carbide powders, making it incredibly hard and wear-resistant. High-speed steel (HSS) just can't compete.

Speed is Money

With carbide, you can run your machines much faster. We're talking 3 to 5 times the cutting speed and feed rate of HSS. This means you produce parts faster, which directly impacts your shop's profitability. More parts per hour means a better bottom line.

Rigidity and Accuracy

Carbide is also much more rigid than HSS. This stiffness is crucial because it reduces vibration during drilling. Less vibration means you get cleaner, more accurate holes with better positional tolerance. It's the key to achieving high-quality results consistently. While the initial investment for a carbide set is higher, the long life and incredible productivity make the cost-per-hole much lower. It's a smart investment for any serious manufacturing operation.

| Feature | Solid Carbide | High-Speed Steel (HSS) |

|---|---|---|

| Speed (Vc) | 3-5x Higher | Standard |

| Hardness | Very High (HRA90+) | Good |

| Rigidity | Excellent | Moderate |

| Cost-Per-Hole | Lower | Higher |

| Initial Price | Higher | Lower |

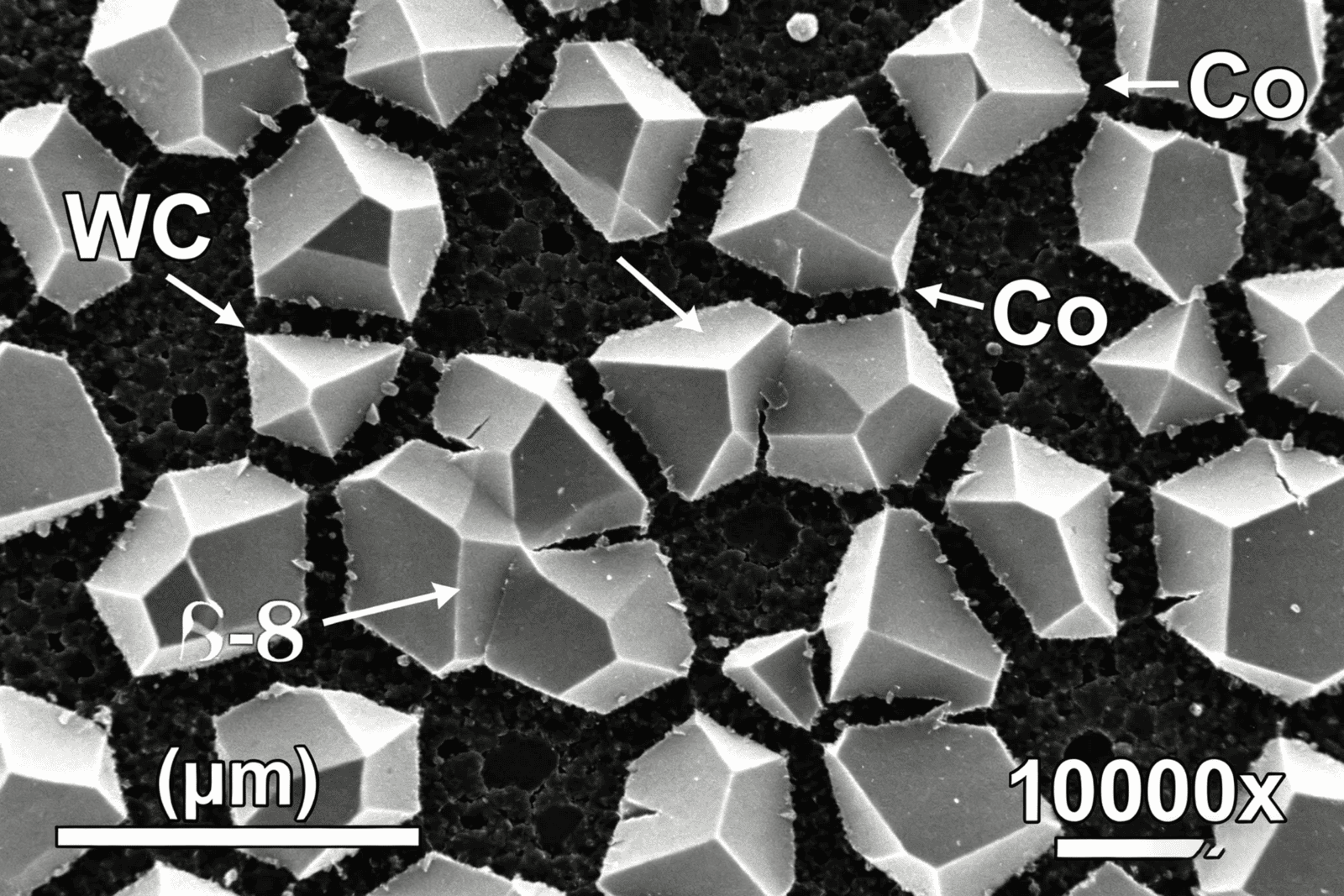

Does the Carbide Grade (Micro-grain) Matter?

Do you think all carbide is created equal? Choosing a low-quality grade can lead to premature chipping and scrapped parts. Understanding micro-grain grades10 is essential for tool longevity11.

Yes, the carbide grade matters immensely. Finer micro-grain structures provide a sharper, more durable cutting edge, improving wear resistance9 and tool life. Coarser grains offer more toughness, which is better for resisting shock in roughing applications. The right grade balances hardness and toughness for your specific material.

When we talk about carbide grade, we're often referring to the size of the tungsten carbide grains in the tool. It's a critical detail that manufacturers like us spend a lot of time perfecting.

The Hardness vs. Toughness Trade-off

Think of it like this: a finer grain size (micro-grain) creates a denser material. This makes the cutting edge harder and more resistant to abrasive wear, which is great for finishing passes and drilling smooth, abrasive materials. However, this hardness can also make it more brittle.

A coarser grain size makes the tool tougher and better at absorbing impacts without chipping. This is ideal for roughing or interrupted cuts where the tool might experience shock. The key insight I've learned is that carbide drills often fail from micro-chipping at the edge, not from slowly wearing down. Choosing a grade with the right toughness for your application can dramatically extend the life of your drill bit.

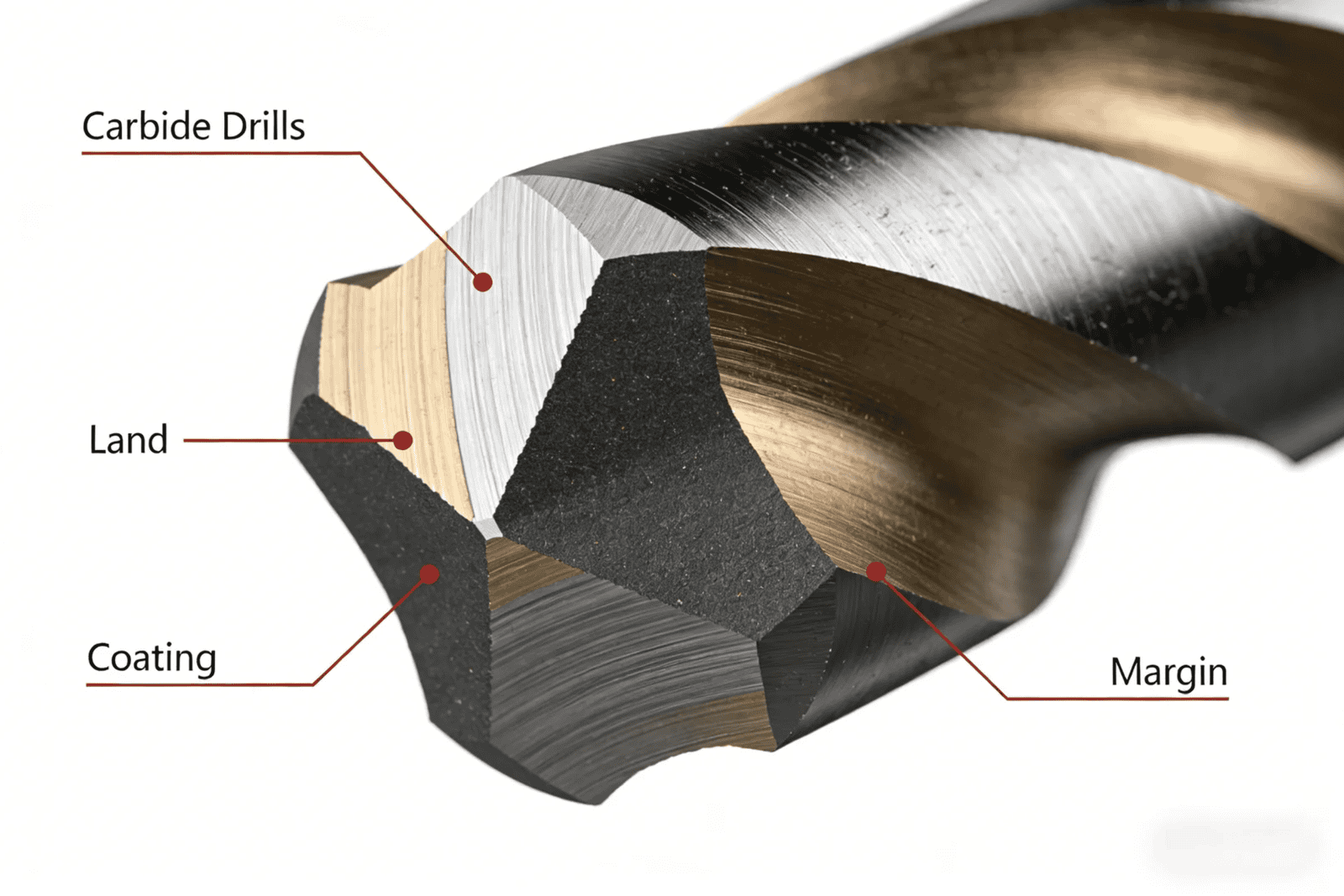

What Geometry and Coatings Are Included?

Are your drill bits grabbing or clogging with chips? This frustration often leads to broken tools and scrapped parts. The right geometry and coating are designed to prevent this.

A high-value set includes drills with application-specific geometries, like different helix angles for chip evacuation12. It also features advanced PVD coatings like TiAlN, which provides a thermal barrier13 and boosts hardness, significantly extending tool life, especially when drilling tough steels and cast iron.

The physical shape and the "armor" on your drill bit are just as important as the carbide itself. Let's look at the two key elements: coatings and geometry.

The Power of Coatings

A coating is a micro-thin layer applied to the drill that acts as a barrier. It reduces friction, increases surface hardness, and provides thermal protection. This allows you to run faster and extends the tool's life.

| Coating | Color | Best For |

|---|---|---|

| TiN | Gold | General Purpose, Wear Resistance |

| TiAlN | Purple-Black | High Temps, Steel, Cast Iron |

| AlTiN | Black | High Hardness, Demanding Jobs |

| DLC | Gray-Black | Aluminum, Non-ferrous (Anti-stick) |

Geometry for Chip Control

The helix angle—the twist of the flutes—is crucial for moving chips out of the hole. A large angle (e.g., 40°) works well for soft, sticky materials like aluminum. A smaller angle (e.g., 15°) gives the cutting edge more strength for hard materials. Also, a small chamfer on the cutting edge is vital. A perfectly sharp edge is weak and will chip easily. That tiny bit of edge preparation makes the tool much more durable.

Does the Range of Sizes Match Your Workflow?

Do you have drill sets full of sizes you never touch? It's a waste of money and clutters your tool crib. A truly valuable set gives you the exact sizes you need.

A high-value set isn't about having the most drills; it's about having the right drills. It should cover the common tap drill sizes, clearance holes, and dowel pin sizes14 your shop uses daily. A well-curated range ensures you always have the necessary tool without paying for extras.

I've seen customers buy massive 115-piece sets, and a year later, only 10 of the drills have ever been used. A bigger set is not always a better set. The real value comes from having the sizes that fit your day-to-day operations.

Focus on Your Core Needs

Think about the jobs you run most often. What are the common thread sizes you tap? For example, if you frequently use M6, M8, and M10 bolts, your set must include the corresponding 5.0mm, 6.8mm, and 8.5mm tap drills. The same goes for clearance holes and dowel pin reaming sizes. A set built around these common sizes is far more valuable than one with dozens of obscure drills.

The Importance of Length

Beyond diameter, consider the length. A good set should have jobber-length drills15 that are rigid and versatile. Always follow the rule: use the shortest drill possible for the job. Less overhang means more rigidity8, better accuracy, and a lower chance of the drill breaking. A set with only long-reach drills is not a well-designed set.

Can the Bits Be Reground or Resharpened?

Are you throwing away expensive carbide drills once they become dull? That's a huge waste of money for your business. Regrinding is the key to maximizing your tool investment.

Yes, high-quality solid carbide drill bits are designed to be reground multiple times. This significantly lowers your long-term tooling cost. A good regrinding service16 can restore the original geometry and even re-coat the drill, bringing it back to near-new performance for a fraction of the cost.

A solid carbide drill isn't a disposable tool. One of the biggest advantages of investing in quality carbide is the ability to resharpen it. This is where you can see a massive return on your investment.

The Economics of Regrinding

Think about the numbers. A new, high-performance carbide drill17 might cost a significant amount. Once the edge is worn, instead of throwing it away, you can send it to a professional regrinding service16. They will use a CNC grinding machine18 to perfectly replicate the original factory geometry and edge preparation. This service often costs only 20-30% of the price of a new tool. You can typically regrind a single drill bit 3 to 5 times, or even more. This drastically reduces your long-term tooling budget.

Quality Matters

This only works with high-quality carbide. Cheaper, lower-grade carbide can be too brittle and may chip or crack during the grinding process. Investing in a premium set from a reputable manufacturer like us ensures the tool body has the integrity to withstand multiple resharpening cycles.

Conclusion

A high-value carbide drill set is defined by quality material, smart geometry, and a useful size range. It’s an investment in speed, accuracy, and lower long-term costs.

Explore the advantages of solid carbide drill sets for improved performance and productivity in machining. ↩

Understanding material grade can help you choose the best drill bits for your specific applications. ↩

Learn about advanced coatings that enhance drill bit performance and longevity. ↩

Discover how precise geometry contributes to better drilling accuracy and efficiency. ↩

Find out how reducing cost-per-hole can significantly impact your shop's bottom line. ↩

Explore the drawbacks of HSS bits and why solid carbide is often a better choice. ↩

Understanding cutting speeds can help you optimize your machining processes. ↩

Learn why rigidity is crucial for achieving accurate and clean holes in machining. ↩

Explore the significance of wear resistance in extending the life of your drill bits. ↩

Understanding micro-grain grades can help you select the right drill bits for your needs. ↩

Learn strategies to enhance tool longevity and reduce costs in your machining operations. ↩

Discover the importance of chip evacuation in preventing tool breakage and improving efficiency. ↩

Learn how thermal barriers in coatings can enhance drill bit performance under high temperatures. ↩

Find out which dowel pin sizes are essential for your machining operations. ↩

Understand the advantages of jobber-length drills for versatility and accuracy in machining. ↩

Learn how regrinding services can save you money and extend the life of your drill bits. ↩

Discover the features that make a carbide drill high-performance and worth the investment. ↩

Explore the technology behind CNC grinding machines and their role in tool maintenance. ↩