Confused by all the solid end mill1 options? The wrong tool can scrap a valuable part. We can help you understand the basics to make the right choice every time.

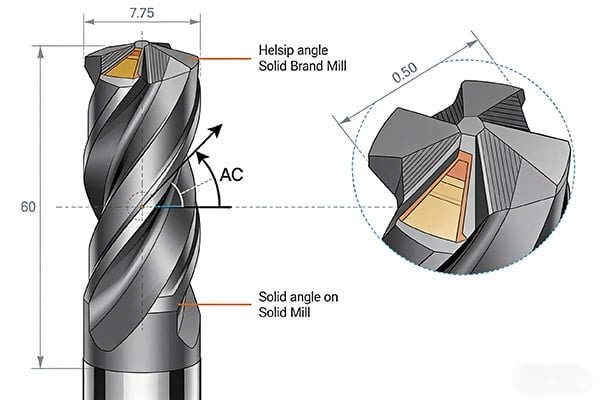

A solid end mill1 is a cutting tool2 made from a single piece of carbide, used for many milling operations3. To choose the right one, consider the workpiece material4, the type of milling operation (like slotting or finishing), and the tool's geometry, including its flute count5 and helix angle6.

I've been in this industry for over a decade, and I've seen how the right end mill can transform an operation. It's more than just a tool; it's the key to precision and efficiency. In our factory, we see it as the "Swiss Army knife" of the CNC machine7. Now, let's dive deeper into what makes these tools so special and how you can master them.

What Are the Different Types of Solid End Mills and Their Applications?

Do you use the same end mill for every job? This one-size-fits-all approach leads to poor finishes and broken tools. Let's explore the different types and their specific jobs.

Solid end mills vary by flute count5 and end geometry8. Flat end mills are for general-purpose milling. Ball nose mills are for contouring and 3D surfaces. Corner radius mills offer strength for roughing. And roughing end mills9 (corn cob) remove large amounts of material quickly.

The type of end mill you choose directly impacts your final part. It's about picking the right tool for the right task. The two main things to look at are the number of flutes and the shape of the tool's tip.

Flute Count Matters

The number of flutes, or cutting edges, is very important. For soft materials like aluminum, you want fewer flutes, like two or three. This leaves more room for the large chips to escape, preventing the tool from getting clogged. For harder materials like steel or stainless steel, you want more flutes—four, five, or even more. More flutes mean a stronger tool core and a smoother surface finish because more cutting edges are engaged with the material at any time.

End Geometry and Its Purpose

The shape of the end mill's tip defines what it can do. A flat bottom is the most common and is used for 2D work like squaring shoulders, slotting, and facing. A ball nose end mill has a rounded tip, perfect for 3D contouring, like in mold making. A corner radius end mill is a mix of the two. It has a flat bottom but with rounded corners, which makes the cutting edge much stronger and less likely to chip during heavy cuts or profiling.

| End Mill Type | Primary Application | Best For... |

|---|---|---|

| Flat End Mill | General Purpose, 2D Milling | Pockets, Slots, Squaring |

| Ball Nose End Mill | 3D Contouring, Surfacing | Molds, Dies, Complex Surfaces |

| Corner Radius | Profiling, Heavy Roughing | Adding strength, extending tool life10 |

| Roughing End Mill | High-Volume Material Removal | Removing large stock quickly |

How Do You Select Solid End Mills Based on Material and Geometry?

Is your end mill wearing out too fast? You might be using the wrong geometry for your material. Matching the tool to the job is key for extending tool life10.

Select based on workpiece material4. For aluminum, use a 2 or 3-flute end mill with a high helix angle6. For steels and harder alloys, choose a 4 or more flute tool with a standard helix angle6. Geometry like flute count5 and helix angle6 directly impacts chip evacuation11 and finish.

I always tell my customers that the workpiece material4 is the first thing to think about. You wouldn't use the same tool for soft aluminum as you would for hardened steel. The material dictates the tool's geometry, from the number of flutes to the angle of those flutes.

Matching the Tool to the Workpiece

Let's break it down. For aluminum and other soft, non-ferrous metals, you need excellent chip evacuation11. This means fewer flutes (2 or 3) and very sharp cutting edges. For general steels and cast iron, a 4-flute end mill is a great all-around choice. It offers a good balance of strength and chip room. When you get into tougher materials like stainless steel, titanium, or other high-temp alloys, you need even more flutes (5 or more) for stability and a special geometry to handle the difficult-to-cut material.

Understanding Key Geometries

The helix angle6 is the angle of the flutes as they spiral around the tool. A standard helix is around 30 degrees. A higher helix angle6, like 45 degrees, is better for finishing and for soft materials because it "lifts" the chips out more effectively. A lower helix angle6 provides a stronger cutting edge, which is good for roughing tough materials. A variable helix, where the angle changes along the flute, is excellent for reducing vibrations and chatter when milling.

| Workpiece Material | Recommended Flute Count | Recommended Helix Angle | Why? |

|---|---|---|---|

| Aluminum & Copper | 2-3 Flutes | High (45° or more) | Excellent chip evacuation11 prevents welding. |

| Steel & Cast Iron | 4 Flutes | Standard (30°-35°) | Good balance of strength and finish. |

| Stainless Steel | 4-5 Flutes | Variable or 35°-40° | Reduces chatter and handles stringy chips. |

| Hardened Steels | 5+ Flutes | Low (below 30°) | Provides a stronger edge for hard materials. |

What Are the Best Practices for Solid End Mill Performance and Tool Life?

Are tool breakages and chatter ruining your production schedule? These issues are often caused by a poor setup. Let's cover the simple best practices that ensure smooth, reliable machining.

Ensure maximum rigidity12 by using the shortest possible tool and tool holder. Use correct speeds and feeds13 for your material. Proper coolant application14 is critical to manage heat and evacuate chips. Always listen for unusual sounds and inspect chips to monitor the cut's health.

Over the years, I've learned that a great tool can still perform poorly in a bad setup. Getting the best performance and longest life from your solid end mill1s isn't about magic; it's about following a few fundamental rules. These are the things we check first when a customer calls with a problem.

The Foundation: Rigidity

Rigidity is everything in milling. Any vibration or movement in the setup will be amplified at the cutting edge, leading to chatter, a bad surface finish, and a broken tool. To maximize rigidity12, always use the highest quality tool holder you can. More importantly, use a tool with the shortest possible length and keep the "stick-out" from the holder to a minimum. Every extra inch of overhang dramatically reduces your setup's stiffness. A stiff, solid setup allows you to run at optimal parameters and achieve the best results.

Monitoring Your Cut

Your eyes and ears are powerful tools. A healthy cut should sound like a consistent, steady hum. If you hear a high-pitched squeal or a loud rumbling, something is wrong. Stop the machine and check your tool and parameters. Also, look at the chips. For steel, you want to see small, tight curls that are straw-colored or light brown. If they are blue or black, you have too much heat. If they are long and stringy, your feed rate may be too low. Paying attention to these signs will help you prevent problems before they ruin your part or your tool.

How Do Coatings and Cutting Parameters Affect Solid End Mill Results?

Are you getting the most out of your tools? Uncoated end mills or generic parameters leave performance on the table. The right coating and settings can double your tool's life.

Coatings like TiAlN15 or AlCrN add hardness and heat resistance, allowing for higher cutting speeds and longer life, especially in hard materials. Cutting parameters (speed and feed) must be balanced. Too fast will burn the tool; too slow will cause rubbing and premature wear.

Think of a coating as a protective shield for your end mill. And think of cutting parameters16 as the instructions you give it. Getting both of these right is how you move from average to excellent machining results. At NV-Tool, we offer a range of coatings17 and provide full parameter support because we know how critical they are.

The Power of a Good Coating

An uncoated carbide end mill is a good tool. But a coated one is much better for most applications. The coating is a micro-thin layer of ceramic material that increases surface hardness, reduces friction, and provides a thermal barrier. This allows the tool to run faster and last longer. A TiAlN15 (Titanium Aluminum Nitride) coating, for example, is a great all-rounder for steels because it performs very well at high temperatures. For aluminum, a super-slick coating like ZrN (Zirconium Nitride) prevents the gummy material from sticking to the tool.

| Coating | Primary Use | Key Benefit |

|---|---|---|

| TiN | General Purpose, Drilling | Basic wear resistance, easy to spot wear. |

| TiCN | Abrasive Materials | Higher hardness than TiN, good for cast iron. |

| TiAlN15 / AlTiN | Steels, High-Temp Alloys | Excellent heat resistance for high-speed cutting. |

| AlCrN | Hard Steels, Dry Machining | Superior hot hardness and oxidation resistance. |

Finding the Sweet Spot: Speeds and Feeds

Cutting parameters are a balance. "Speeds" refers to the spindle RPM, and "Feeds" refers to how fast the machine moves the tool through the material. The goal is to find the sweet spot. If your speed is too high or your feed is too low, you'll generate too much heat and burn up the tool. If your speed is too low or your feed is too high, you risk breaking the tool. The key is to calculate the right chip load—the thickness of the chip each flute cuts. Start with the manufacturer's recommendations and adjust based on the sound of the cut and the chips you are making.

Conclusion

Understanding your material, application, and setup is key to choosing the right solid end mill1. Mastering these basics will boost your efficiency and the quality of every part you make.

Explore this resource to understand the fundamentals of solid end mills and their applications. ↩

Learn about various cutting tools and their specific uses to enhance your machining knowledge. ↩

Discover various milling operations and their applications in machining. ↩

Discover how different materials influence tool choice for optimal machining results. ↩

Understanding flute count can significantly impact your machining efficiency and finish quality. ↩

Learn how helix angle influences cutting efficiency and tool performance. ↩

Learn about CNC machines and their role in modern manufacturing processes. ↩

Explore the significance of end geometry in selecting the right milling tool for your projects. ↩

Understand the advantages of roughing end mills for high-volume material removal. ↩

Explore best practices for maximizing tool life and performance in machining. ↩

Explore the importance of chip evacuation in maintaining tool performance and longevity. ↩

Discover how maximizing rigidity can improve machining results and tool life. ↩

Understand the concepts of speeds and feeds to optimize your machining processes. ↩

Understand the role of coolant in managing heat and improving machining efficiency. ↩

Discover the advantages of TiAlN coating for high-speed cutting applications. ↩

Learn about the balance of cutting parameters for optimal machining results. ↩

Explore how coatings enhance tool performance and extend tool life in various applications. ↩